In this Fly Fishing Special, I have tried to completely elaborate for you the topic of today's so many popular UV varnishes, resins and glues, which for me represent a kind of symbol of the 21st century in the fly tying. At the same time, thanks to this topic, I returned a bit to my original field of chemical engineering, but you do not have to worry - I tried to eliminate the scientific approach and not overburden the article with it, but rather enrich it! ;-) If you are interested in this topic, I will be very happy if my next publication becomes a source of useful information and inspiration for the moments spent at your fly tying vice - when inventing new patterns, or when innovating the existing your favorites flies!

As I have already outlined in the annotation, the use of UV resins and glues has become very popular in recent years in tying fishing flies, and these special viscous liquids have gradually found a place not only in tying and finishing large streamers for fishing freshwater and saltwater predators, but "even in the fly tying of traditional patterns of flies, even the smallest dimensions intended for catching both salmonid and other species of freshwater and saltwater fish.

Today, it is no longer unusual for UV resins of various viscosities to be used to tie popular tungsten and traditional nymph patterns for fishing on rivers and lakes, "epoxy" buzzers designed mainly for fishing on still waters, but also all kinds of wet flies, lures, small streamers, egg imitations (Egg Flies), saltwater crabs, shrimps and many other types of artificial flies.

It can be said that UV resins and glues have basically replaced the hitherto popular two-component epoxy resins, which were used mainly for finishing specific types of predator and trout streamers - especially in the creation of their hard heads. These resins were great in their time and for these purposes, and probably even today some fly tiers still use them when tying certain types of flies, but from today's point of view and in comparison with modern UV resins and glues , of course they had a few disadvantages - "longer/shorter "curing time, which was usually 5 minutes from the time of mixing the 2 components of the glues together, with the fact that the absolute curing of the resin was in fact only a few hours.

Thus, the epoxy resin solidified slowly for certain purposes - with a larger amount it flowed under the influence of gravity to the lower part of the fly, which had to be manipulated and rotated differently either by hand or using various slowly rotating discs, which ensured even distribution of glue on the fly. On the other hand - for certain operations and modifications, the gradual solidification of the epoxy was relatively fast, so you did not always succeed in achieving the original intention on the fly, because the shaping of the glue was relatively limited in time. Other disadvantages include the gradual change of color when the epoxy resin is exposed to daylight (just UV), and therefore practically all clear epoxy resins gradually turn yellow.

All these mentioned problems of epoxy resins have started to be solved by previously not so commonly available UV resins and glues, the main advantage of which is the immediate reaction of their components with ultraviolet (ultra-violet = UV) radiation. In this respect, I will not burden you with matters related to the reaction of individual components of UV glues when exposed to UV radiation, the important thing is that as soon as we shine a sufficiently strong UV flashlight on the applied UV glue, the glue will harden in a few seconds! This is a very important factor in the tying of flies, because we can immediately "record" the condition and fix the shape of the adhesive, which is suitable for us flies and this is exactly the huge advantage that epoxy resins lacked! We will achieve much more attractive results and work on such a fly is several times faster, more comfortable and much more efficient when tyinga larger number of patterns using UV glue!

But in order to get to specific UV resisn and glues and their primary use in the fly tying, I have categorized them for you into basic groups in direct connection with their viscosity/density, which strongly influences how well we will be with varnishes work, how fast and how strongly they will be cured upon "contact" with UV radiation in the form of a UV flashlight and most importantly - what types and sizes of flies are suitable to tie with individual types of UV resins in the most ideal case!

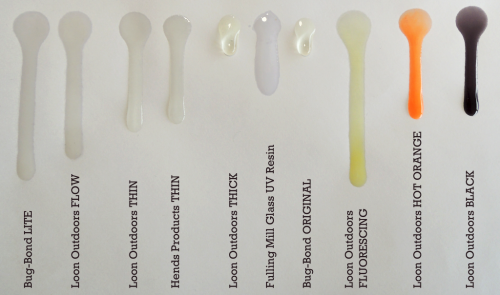

FLOW & LITE UV Resins (Little viscous): These very thin UV fly finish from our offer include UV Clear Fly Finish Loon Outdoors Flow and also UV Glue Bug Bond Original Lite. These are UV resins with a very low viscosity and it can be said that I would compare their consistency to, for example, silicone oil! The tying materials absorb them very well and quickly - that is why you have to be very careful when using them on flies with dubbing and with a larger amount of absorbent materials. For such types of UV resins , it is really advantageous to work with special thin attachment tips, which are part of the package for all Loon Outdoors UV fly finish products. These attachment tips can be purchased with Bug Bond adhesives - Bug Bond Tip Kit. Alternatively, for really detailed work, work with a dubbing needle, which is, by the way, one of the really useful and necessary aids in general when working with UV resins and glues.

This type of very thin UV fly finish is most ideal to use when tying the smallest flies, but due to the low viscosity you can use them to replace, for example, ordinary head varnishes and with subsequent hardening to "varnish" even fly heads of all sizes. It is also a great type of UV resin for finishing the thin glass surface on the bodies of specific "Epoxy Buzzers" (Glass Buzzers). This will speed up your work much compared to using epoxy or ordinary varnish, for which you never know exactly how the thread will absorb it as a result and how much it will "fall", or super glue, which tends to whiten in water and "burn" or degrade other materials on the fly even during the curing reaction! The UV resins mentioned in particular are relatively very clear, so they do not distort the original colors that they overlap.

If I had to choose for myself and I did so historically before the actual comparison, I would choose UV Glue Bug Bond Original Lite again, which seems much harder and generally more stable after curing.

THIN UV Resins (Medium viscous): In this case, it is safe to say that these are very versatile UV resins/glues, which will probably find the widest application, both for smaller flies of all types, but also for medium-sized and, in the last case, large streamers. These UV resins include UV Clear Fly Finish Loon Oudoors Thin together with a smaller and much more affordable equivalent of the UV Clear Fly Finish Thin Hends, which can also be purchased in a set together with a UV flashlight. I would compare the consistency of these thin UV glues to fresh and non-crystallized honey, so the absorbency of these UV resins by tying material is much lower and slower than previous types - so you have much more time to cure the surface with a UV flashlight before UV varnish begins soak slowly!

So you can use it, for example, when "painting" the thoracic sheaths/wing germs on classic nymphs - with regard to higher resistance and longevity of flies, I began to practice this, for example, nymphs such as Pheasant Tail Nymphs (PTN), Hare's Ears (HE), etc., where I imitate wing germs created from the strands of a pheasant or turkey tail feathers with this UV glue and harden it with a UV flashlight. Furthermore, I use this type of UV glue for the backs of Gammarus & Shrimps, as well as for larger "epoxy" buzzers, where I want to achieve the effect that the body of the fly "wraps around" UV resin. Often, closed bubbles will form in such a "cover", which is of course a welcome effect for me and perhaps also for fish, because even with live chironomid pupae, air bubbles are trapped under the cover, which creates a shiny effect underwater! The last use of these UV fly finish is when tying small to medium-sized trout or perch, chub and asp streamers, on which you do not want the glue to have too much! I also like to use these glues for pouring and fixing the bodies of Sparklers and smaller streamers, which i tie from tinsel. There is no danger of their destruction after contact with sharp trout teeth.

In this case, I must say that although the viscosity of both resins is very similar, the resulting hardness after exposure to UV radiation is quite different. UV Clear Fly Finish Loon Oudoors Thin is very hard and also resists digging, abrasions and stabbing with a dubbing needle. UV Clear Fly Finish Thin Hends is rather relatively flexible after curing, so you push it by digging, but after a while it returns to the same shape. But this is definitely not a disadvantage! On the contrary, it is a property that is very useful for flies, where the flexibility of the surface is advantageous and, conversely, glass hardness is undesirable! The transparency of both adhesives is very similar - very clear with a really light yellow tone.

THICK UV Resins & Glues (Very viscous): These UV glues include two main representatives with practically identical properties! This is the UV Clear Fly Finish Loon Outdoors Thick and its traditional and very popular predecessor UV Glue Bug Bond Original - probably the best known and historically longest used UV glue for tying flies! These glues are very viscous - I would easily compare their consistency to - well known among fly fishers - AQUASURE wader repair glue. It is therefore absorbed into the material really slowly - in the case of thin synthetic fibers when tying streamers, etc. In the case of dense material (dubbing, thread, fur, etc.) it is practically not absorbed and after curing it rather forms a thick crust on its surface. The time for shaping and working with it is therefore practically unlimited (if you do not tie outdoors or in strong access to daylight, which of course all UV fly finish slowly but surely also cures, but not as fast and intensively as an isolated and direct source of UV radiation = UV flashlight).

These UV adhesives are therefore excellently and preferably suitable for finishing medium to large streamers intended for fishing large predators. We mainly use them to create attractive heads of imitations of small fish, or their whole bodies. A huge advantage is the slow setting of the glue, so we can gradually adjust its surface and shape, for example with a dubbing needle, and as soon as we are satisfied with the result, we turn on the flashlight and cure the glue on the fly! These UV glues are also great for the purpose of applying a larger dense amount of them - Egg Flies - imitations of transparent fish eggs - without applying and gradually curing a larger number of individual layers.

The transparency of these two glues is probably the "worst" of all the clearcoats mentioned. Of course, this is not terrible - you can judge for yourself from the picture that a slightly yellowed tint is noticeable, but otherwise the glues are clear, very hard and with a glossy surface. But if I had to choose again, I would choose - just like years ago - UV Glue Bug Bond Original again! Although both UV glues are really very similar in all properties, Bug Bond is simply harder than Loon and we can really talk about glass hardness (in the case of reliable curing with a quality UV flashlight).

SPECIAL & COLORED UV Resins (Various viscosity): Of course, UV resins and glues special and colored, must not be missing in this article - just because they are really used today to create various attractive "trigger" points for fish strike, whether they are colored and UV stains and drops on chest of Tungsten Jigs and Perdigon Nymphs, Buzzer cheeks, streamer eyes and heads of wet flies and stillwater attractor & lures, etc. These are simply very popular and modern UV resins, including mainly UV Fly Finish Loon Outdoors Colored, which is available in an incredible range 16 classic and fluo UV colors as well as UV Clear Fly Finish Loon Outdoors Fluorescing (viscosity corresponding to a very thin UV varnish FLOW), which, however, does not shine in the dark after lighting with a lamp, as one might think, but at greater depths, when classic colors changes its character - thanks to the poor range of light radiation - it this varnish is more visible for fish. It works on a similar principle as UV paints - shine a UV lamp into your fly box and you will find out what you may not have known until now! ;-)

It could be said that colored UV resins are nothing more than clear UV resins (according to their medium viscosity, I would suggest them for the THIN version - thin UV fly finish) with an admixture of fine colored powder pigments. So take into account that the color density of these color UV resins will never be the same as, for example, color nail polishes. These are more of a touch of color! At the same time, take into account that the darker the color, the longer the colored varnish will cure, or one of the defects may occur in this type (instability of curing, which is manifested, for example, by cracking or peeling).

Therefore, colored UV resins are great for highlighting certain parts of the fly in the form of color tone, overflow or dot. If you want to support the color effect, do not use, for example, light colors on the dark parts of the fly, which "overcharges" the colored resins, and always mix the bottle thoroughly with a long needle, for example, before using the colored varnish! If you want to have the most saturated color, make more thin layers on top of each other - the more layers you make, the greater the color density of the UV varnish.

"DEFECTS" Of UV Resins: During the testing of all mentioned UV resins and glues, I also encountered a few defects, which must be mentioned in order for the processing of this topic to be complete. However, it must be said that - except for the last case - this is not absolutely essential, because I am convinced that I supported the defects mainly by testing UV resins on a smooth surface, which we practically do not encounter on the surface of flies, and I must say that I have not encountered anything similar with all UV resins during tying and subsequent use.

1) Cracking & peeling of UV varnish I observed when I tested UV resins on a smooth surface with digging, piercing and tapping of - specifically with UV Clear Fly Finish Loon Outdoors Flow, UV Clear Fly Finish Loon Outdoors Fluorescing and UV Fly Finish Loon Outdoors Colored in black/dark colors. Here I assume that in the first two - FLOW - versions, the curing is not completely stable due to the lower content of "binders" of the paint, which enter into reaction with the other components when initiated by UV light. If you have read all of the above carefully, you can basically conclude that the denser the UV resin/glue, the harder the resulting surface after curing with a UV flashlight (Loon, Bug Bond). With black UV resin, I explained the potential problem with peeling above - and therefore, the more and the darker the pigment, the worse the cure, because the UV rays do not penetrate the glue as perfectly as in the case of lighter colors or completely clear UV resins.

3) Surface grease - "effusions" is a very common phenomenon in all UV fly finish. Grease/effusions are formed on the surface of the cured UV resins as a by-product and undesirable product of the reaction for us. But such a problem can be solved very easily! Use a quality UV flashlight, wipe greasy effluents from the surface with a damp cloth, or (larger amounts of exudates when using, for example, a weak flashlight or a large amount of UV glue at once) wipe the surface grease with the effusion remover you buy today at every drugstore.

3) Fulling Mill Glass UV Resin - When testing this type of glue, I was initially excited about its great clarity, medium viscosity and beautiful gloss, but when I went to test the drop for its hardness and resistance, I found that even after several attempts to cure the reaction simply did not occur and the glue was still in its original consistency - I simply could not cure this glue, which is of course a fundamental problem.

Therefore, based on my research, we immediately withdrew the product from sale, reported the problem to Fulling Mill, and at the same time I urge all our customers (so far no one has contacted us with such a problem) to contact us immediately in case of the same defect in this the product came across - in that case, of course, we will offer everyone an adequate replacement!!!

Quality UV Light = Absolutely MUST HAVE! As the title suggests - you can have the most expensive UV resins, but if you don't have a strong enough UV flashlight, all your work with UV fly finish will be useless, because you can't harden them with a weak UV flashlight! I have this experience from previous years, when I first decided to compromise the issue of buying a cheap UV flashlight, which needed 3 AAA batteries for its drive, whose energy was very quickly depleted and the flies happened to me that the glue peeled off from a damp and uncured surface (streamer heads), or I - with a weakening intensity of UV radiation - was not able to harden the glue at all!

That is why I have been saying since then - although I have written a lot of information in this article that does not completely 100% confirm this - that UV adhesives are usually on a similar basis, but what is most important for their reliable curing is a quality flashlight radiation! Personally, I am therefore very satisfied with the UV Infiniti Light Loon Outdoors, which can be recharged very quickly via USB, but at the same time work with it connected to the network - even in the event of a complete discharge! In addition, it lasts a really long time on one charge, so for me this is absolutely clear - although expensive, but very reliable - now an uncompromising choice! Other UV flashlights that I would easily recommend include the UV Light Bug Bond Professional and also the high-quality UV Bench Light Loon Outdoors or UV Nano Light Loon Outdoors.

I hope that I have introduced you - those who were not quite clear on this topic or something completely new to them - in this article in detail and, above all, clearly to the world of modern UV tying resins and glues, and perhaps even inspired and motivated you for moments at the vice! If so, I am very happy and will look forward to another article or gallery! Aleš 🎣🍀